Shin Mone Commitment: Low-Carbon Manufacturing, Sustainable Development, and Shared Industry Growth

Shin-Mone Screw Co., Ltd. was founded in 1990 by Chairman Mr. Kuo Yung-Chung in Gangshan, Taiwan. The company began by producing general machined parts and standard screws, primarily serving domestic trading partners. In 1997, Shin-Mone entered a key partnership with global furniture brand IKEA, shifting focus toward the specialized production of furniture screws.

As customer expectations and industry standards continued to rise, Shin-Mone responded by reinforcing its commitment to quality. This led to the achievement of ISO 9002 certification in 2000, marking a significant milestone in the company's quality management journey.

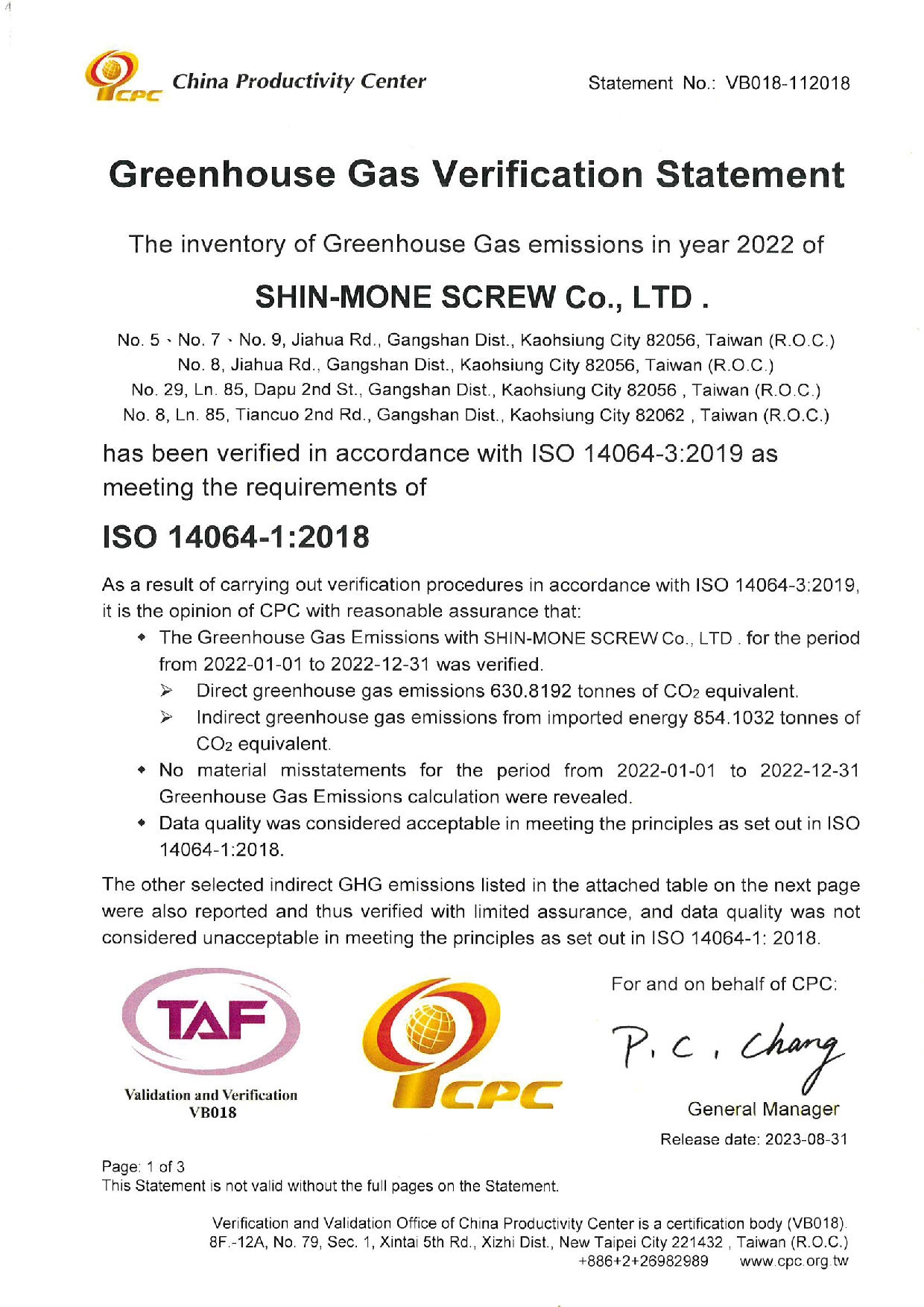

In line with global environmental trends and corporate responsibility, Shin-Mone has since adopted low-carbon manufacturing practices. This initiative reflects the company's broader mission to pursue sustainable operations while contributing to long-term growth and mutual success within the fastener industry.

Strategic Transformation and Growth through Innovation and Quality

In 2005, the company shifted its focus to manufacturing technologically advanced special screws, increasing machine capacity and expanding the factory to meet customer demands for a diversified product line. As competition intensified and emerging markets in Southeast Asia and China grew, more manufacturers entered the standard screw market, offering customers greater purchasing options. This highlighted the importance of adding value to our products to remain competitive in the fastener industry. Under the chairman's leadership, the company prioritized quality improvement across all levels, guiding staff and technicians in enhancing quality awareness. In In 2005, the company began implementing the TS 16949 standard, achieving certification in 2007 after two years of preparation. The quality management system has since been updated to IATF 16949.

Today, our company specializes in a diverse range of screws, including custom automotive and construction screws, as well as high-expansion and high-shrinkage screws. serves OEM and ODM markets, while actively pursuing direct export opportunities.

Today, our company specializes in a diverse range of screws, including custom automotive and construction screws, as well as high-expansion and high-shrinkage screws. serves OEM and ODM markets, while actively pursuing direct export opportunities.